Interpack 2026

10 December 2025

THE CAM STAND AWARDED FOR SUSTAINABILITY AT CPHI 2025

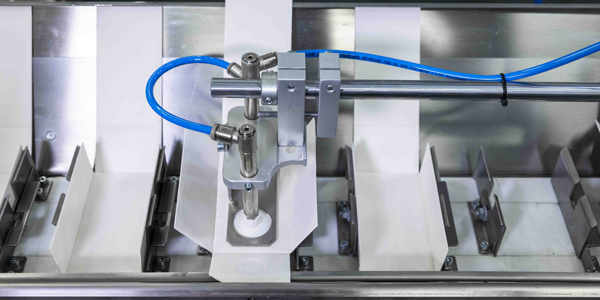

13 January 2026The system integrates four critical components to manage product handling and carton preparation. The Automatic Liner Feeder significantly boosts operational autonomy by drawing liners automatically from two separate magazines, minimizing material replenishment downtime.

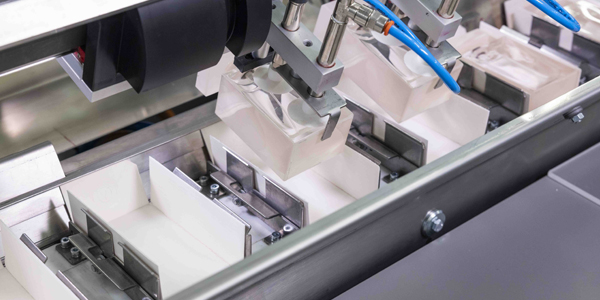

For product handling, the Pick and Place system performs a precise operation for bottles, safely removing them from their transport pucks and accurately positioning them into the open cartons.

Furthermore, a dedicated group equipped with a piston for the liner flap containment is utilized. Its primary function is to press down and manage the flap, which is crucial to facilitate accurate final carton closure without obstruction.

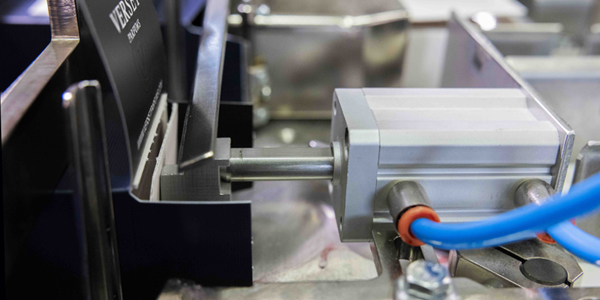

Finally, a photocell is strategically positioned to check for the presence of bottles in the bucket (or product carrier). This critical checkpoint prevents incomplete or empty cartons from proceeding down the line, maintaining high product integrity standards. These integrated features work in concert to deliver a faster, more reliable automated cartoning process, improving overall throughput and reducing manual intervention.